Final Report from Saint Marie, Haiti (2010)

FINAL REPORT OF Sainte Marie Pilot Project. Port Au Prince, Haiti, 2010

For the safe remediation of human waste and its transformation into an optimum fertilizer

by Howard-Higgins EcoSan, thermophilic composting .

Funded by Catholic Relief Services (Haiti) and New Directions Foundation (London)

Author: Richard Higgins, agricultural researcher and leading exponent of the science of thermophilic composting and its effectiveness as a waste management tool.

Initial response at WASH cluster, Port Au Prince

Having been approached by the regional co-ordinator, for Global Water Initiative, Central America, Catholic Relief Services, Richard Higgins was introduced to the regional director, he agreed with Richard the pressing need for averting sewage from water borne systems to a DRY method to avoid the mounting problems of: increased risk of disease, further ground water contamination and combined solution for the hygienic disposal of all organic wastes produced in refugee camps. He was subsequently contracted by the group, who have been in Haiti for fifty years. Project Description To erect five urine separator latrines for camp 1 at Sainte marie, Canape vert, Port Au Prince for the purpose of Total Nutrient Recovery (TNR) and rendition of fecal matter and urine into an optimum fertilizer by building a dry thermophilic composting operation to digest the waste of 200 users per day. This was done in conjunction with the source separated waste from the camp and the neighbouring convent. Specific Activities Preparation: On arrival to initiate the project we utilized two 3 metre open pit latrines that had already been dug, were completely open and were in use. We capped off these dangerous latrines with a concrete block surround and a plywood floor. Then the urine separator collection units, designed by NDF (Haiti), were installed using the converted standard Oxfam footplates. Five gallon buckets being placed beneath the raised wooden platform for collection of solids. Provided in the latrines housings were medium buckets and instructions to ‘cover over’ with a scoopful of the collected earth, ash and dry grass etc., There were no complaints to this procedure as upon using these latrines there was found to be no smell. Also the introduction of the ‘footplate’ system as opposed to the conventional seated toilet arrangement presented no complaints . 2 Richard Higgins has also a new and very economical design for a urine separator sit down toilet for the disabled and very young that were found to encounter problems with either ease of use or a misunderstanding of how to use the squat plate. Note: In the light of the Cholera outbreak NDF generally recommends the use of squat plates as opposed to the seated toilet arrangement as an added precaution for the prevention of spreading fecal contamination.

Break down of ‘Cash for Work’ presented to the project funders CRS

We employed 2 trainee managers at 380 HTG per day each one plastic picker to separate from sweepings at 180 HTG per day one laborer at 180 HTG per day and one latrine cleaner at 180 HTG per day TOTAL COST FOR LABOUR for running this site was 9,100 HTG per 7 days.

Design of latrine housing and squat plate urine separator

The latrine housings were built on a surround of concrete blocks joined with a mixture of cement and earth and were boarded over with 18mm plywood, which was affixed to the blocks below. The walls of the 20 Square foot latrine were 12mm plywood and were supported on 2X4 timber, the door the same. A tin roof was nailed to a similar frame. The size was determined for ease of access for mothers with children. However we found that mothers did not accompany children to the latrines, rather the managers were oganising lines of waiting children, some as young as 3 or 4 years old, to enter the latrines in an orderly fashion, instructing them how to ‘cover over’ with the supplied medium. The raised footplate collector was constructed out of 2X3 timber, sided by 12mm plywood, accommodating the Oxfam footplate as the top surface. Beneath this construction was placed the standard 5 gallon bucket, which was easily removed from the back of the footplate when replacing with an empty clean one. New Directions Foundation have now sourced an appropriate 30 litre bio degradeable Bio liner that fits snugly into the 5 gallon bucket and suits perfectly the time frame for complete destruction of the liner and its contents with the first 14 days of the composting process.

The urine separator device

consisting of a rectangular 5 litre juice bottle cut diagonally in half was wired to the underside of the Oxfam squat plate with a slight slope for drainage. This was connected to a 5 litre juice bottle, the caps for both being retained on each bottles and a small hole was drilled to accommodate the standard 12mm clear plastic pipe. The collection bottles being placed visibly outside the latrine housing. This serves as a visual indicator that when full, it is time to unscrew the cap, replace with an empty bottle, and replace the cap. This is the original design that Richard Higgins put into use in West Bengal, India in 1997 and is detailed in his title ‘The Lost Science of Organic Cultivation, (1977).

Housing Construction materials needed to construct a single Latrine

Dimensions from front to back and side to side are 4 ft square, and sides 5ft high, roof height being 6ft 6″ 14 concrete blocks 1/2 bag of cement 8 3X2 timber @ 6 ft 3 3X2 timber @ 6ft 6″ 2 steel hinges and screws 1 wood turn door bolt 70 2″ wire nails half inch plywood 5 4ftX5ft 2 sheets tin roof X 6ft 1 Oxfam foot plate 1 piece plastic pipe 2ft 6″ 1 discarded plastic 5 Ltr. water bottle 1 flat juice bottle cut in half (urine separator) 2 10″ pieces flexible wire to hold juice bottle in place. 3 foot length of clear plastic pipe

Raised box construction for squat plate

Half inch plywood 4 3X2 timber X 16″ 2 31″X15″ 1 23″X15″ 4 2.5 inch screws 2 23” X 15” sides ½ inch ply 31″ X 15” .

Hand washing facility

It is essential to have a hand washing facility outside the latrine housing with instructions. In this situation however we were unable to obtain the CRS foot operated water pump system that dispenses minimal water for hand washing. We only had signs advising hand washing. However there were no reports of any disease from the lack of hand washing facilities directly outside the latrines.

Design of composting site

Flat areas are required to operate this system successfully. As this derelict garden , we were allocated, was on a slope we terraced four flat areas for the installation of two double pallets on which to build the composting heaps. It is imperative that there is a fresh water supply for minimal irrigation of compost heaps. Protection from rainy season The already composting fecal matter (contained in the Bio liners) is already separated by layers of the added medium in the latrine buckets, which is the key to odour prevention.

Bucket System with Bio-liners

The full buckets are taken from the housing to the compost area and are exchanged with newly lined buckets. The Bio liner is then simply slid out of the bucket onto the compost heap, at the rate of 8 liners per double pallet. Each layer is then covered with more composting medium, namely grass, straw or swept leaves etc., and before the next layer is added a layer of vegetable waste is prepared beforehand. The heaps are built up over 7 days thus each double pallet contains 56 Bio liners. To protect from the falling rain we covered the heaps with tarps. This allowed the rain to run off without coming into contact with the live material on the heaps. The running surface water passes unheaded below the pallets.

Secure tool storage

A small secure shed is required for storage of the necessary tools; and for this size site they are: 2 stable manure muck forks. 1 X 90 degree compost rake (large) 4 operation time charts, encapsulated for weather protection, on stakes in ground.1 black permanent marker pen. 1 wheel barrow. 2 flat spades.

Daily Operation of site

The full operaters Manual contains this information and operational precedure.

Please see video footage of the system in daily operation being visited by various NGO’s. • PeePoo bags Oxfam were present www.suaglon.co.uk on one open day and Richard offered to take their PeePoo bags at the rate of 100 per day. These were placed into, the composting system. The bag and their contents disappearing in the first 14 dyas of the process. These PeePoo bags are designed for refugees that have no sanitation facility whatsoever and are a safe and hygienic method of collecting feces and urine for disposal. Then only fresh water is applied to maintain moisture levels. The remainder of collected urine can be used as a diluted fertilizer feed to fruit trees. Where there is suspected worm infestations in the population urine, the material can be heat treated for sterilization. in the sun for a set number of hours. Developments Richard has sourced 30 litre Bio degradable liners in the UK, that will fit into the 5 gallon buckets. He has tested them at his training centre and they, like the PeePoo bags completely vanish, with their contents, in the first 14 days of the process.

All in all methods of DRY sanitation

This method of DRY sanitation should be addressed as a far more comprehensive solution to the sanitation problem anywhere in the world. With the rapidly declining mineral phosphorus reserves, world agriculture and food production will become more and more expensive to operate.

Results • Acceptability

There were no complaints during the pilot project, only comments of satisfaction from the camp residents. A few ACF porta cabin latrines had appeared on the other side of the site but people preferred to use our latrines even though they were further away from their accommodation and we did not have the option of sit down toilets. These sit down type toilets were kindly removed by ACF at our request so as not to detract from our pilot project.

Scientific

Apart from the early work of Howard in the title ‘The Lost Science of Organic Cultivation’ Higgins set up a trial for full analysis at the Waltham pet center in the UK. This is a research centre owned by the MARS group where dogs are bred solely for nutritional purposes. 200 dog wastes were added daily in paper bags and the resident scientists analysed the ‘30 day’ old product, at four different time intervals. All samples were found to be free of pathogens and toxocara parasite free too. The product was found to be ‘chemically equal to earth’,. We did not have the facility to have the end product tested in Haiti, nor were we equipped with the basic long probe thermometer but by following the strict time pattern and instructions of the operating system the safe remediation of human effluent can be effected to this same level. However to meet the environmental regulations of the modern age we advise the use of the HH-2 units to protect human health.

Accessibility

Our five latrines were all on one side of Camp 1, at Sainte Marie but for the 200 people camp, it was not too far to walk to one of our latrines.

Processing to fertilizer

Finely divided, saleable fertilizer was achieved in 90 days from day 1 of the operational system

Viral disease elimination

(see previous graph). ECONOMY if the compost is normally stored in heaps, as suggested, for the full 90 days. A rate of reduction of 4:1 is achieved in the process from the beginning to the end. Thus the 10 space required is considerably small for the amount of waste being digested and fertilizer produced. For every 4 cubic meters of material entered onto the pallets one cubic meter of finished compost is achieved, which equals one ton. The fact that this potent fertilizer can completely replace the need for artificials of any kind and that the only running cost in its manufacture is labour, means that it is an economically viable option to the chemical system of farming. As the sources of commercial mineral fertilizers decrease so the prices will increase. (ref. Dr. Rosemarrin on Phosphorus, NDF web site, now suaglon web site)

NGO’s visiting site

A large number of visitors attended the demonstration site over the open days. These were people from the NGO’s listed in the credits at the end of the Film II that is included with this report. They all found it extremely informative and interesting. They had all been invited to a celebration lunch before the talk and were seated 20 feet from the compost heaps that contained approximately 7,200 human wastes. They were un aware that they had been sitting in front of such an operation. (no smell, no flies) Further recommendations Due to the outbreak of Cholera in Haiti and due to the large amounts of conventional latrines we recommend that the sludge tankers be diverted far from the habitable areas and taken to flat open fields . We can then process fecal matter safely without causing any danger to the city inhabitants. (consult for further details) Simply pumping sewage from one hole in the ground to another is not solving any more than an immediate removal problem and is indeed the reason that the entire water table in Port Au Prince has been polluted.

Further technology In the UK

The Howard Higgins system has been designed for rural communities with an enclosed twin Hot Box system, each consisting of a 1 meter cube. These 2 meter cubed, known as HH-2 Hot Boxes safely contain all live waste for the critical period. Thus it passes all the Environmental Health regulations of the west. The pair worked alternately can digest the sanitation waste, in the new Bio liners, of up to 24 houses, continuously. Thus this system is the most compact and efficient sanitation system. (consult for further details)

The HH-2 Horticultural System

We also instruct the method of application of the potent fertilizers produced. (consult for further details). New Directions Foundation has different models (with automatic data recording) for Hot Chamber composting according to the capacity required. As consultants we can offer consultancy for setting up a large scale low tech composting operation along the same lines as those herein for the immediate disposal of human feces and urine from Port Au Prince or from anywhere within an organised setting.

Red Flags

It is essential that any site is set up and run by a qualified HH-2 consultant at the outset. IE., as supplied or trained by New Directions Foundation/Good Gardeners International.

Conclusion

This pilot project at Sainte Marie has proved a 100% success. There have been no problems reported and we have only had comments of praise for the lack of smell at the latrines and the state of cleanliness of the refugee camp due to the operational system requiring all forms of organic waste to be swept up and used in the system. It is hereby concluded that DRY sanitation via the HH-2 Hot Box system provides the least risk for the spread of disease and the highest benefit to agriculture, wheras the passing of human waste into any water borne system, increases risk of disease, ground water contamination and is less beneficial or is completely removed from agriculture. As supported by the statement made by the World Health Organisation. Contamination of drinking water from human sewage causes more death on the planet than from any other cause. www.newdirectionsfoundation.org Enclosed with this report is a VIDEO LINK (redundant link) for Open days at Sainte Marie, featuring the comments of Professor Bob Reid, WEDEC (Water Engineering Development Council). This group recommends appropriate technology for NGO’s.

Video Footage

Full length films about the operation of the entire process can be viewed on the Sustainable Agriculture London web site at sugalon.co.uk under media or viewed directly via these links

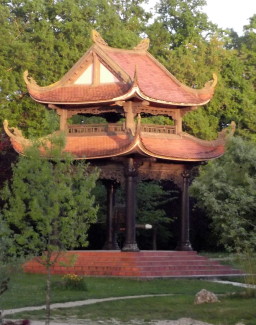

The Plum Village Buddhist community are located here with 3 farms. The system had been discovered on the internet by the funders of the Plum Village community; the wealthy Astor family. Under their instruction the first HH-2 system was ordered and shipped to France.

The Plum Village Buddhist community are located here with 3 farms. The system had been discovered on the internet by the funders of the Plum Village community; the wealthy Astor family. Under their instruction the first HH-2 system was ordered and shipped to France.

but this had not stopped the onslaught of pests and diseases. A meeting was called for members of their three farms to attend. The aim being to generate an optimum fertiliser/soil conditioner from their own waste.

but this had not stopped the onslaught of pests and diseases. A meeting was called for members of their three farms to attend. The aim being to generate an optimum fertiliser/soil conditioner from their own waste.